Seppo Suomi Oy

In future at Seppo Suomi Oy’s machine shop in Hartola, Central Finland, one shift will be manned and the remainder handled with the assistance of automation. ”From now on we’ll have just one manned shift at our works. By automating the following shifts we’ll gain vital cost-efficient additional capacity”, emphasises Seppo Suomi Oy’s Managing Director […]

Kytola Instruments: FMS up and running

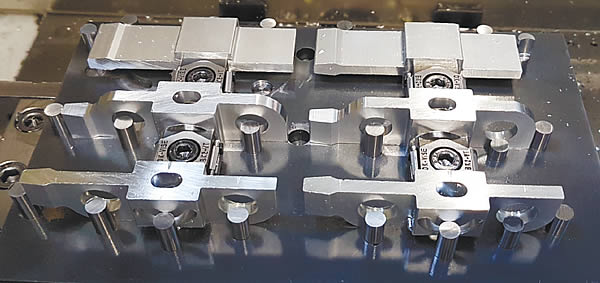

Improving flexibility Kytola Instruments, who has now installed a Flexible Manufacturing System (FMS) from the Finnish company Fastems, are extremely happy with their investment. Together with 14 new tooling blocks supplied by OK-VISE Oy, including several Fixturing Concept and Multi-Rail setups, the system has improved their flexibility significantly. In total, Kytola is machining today about […]

A small workshop using OK-VISE

MJM-Koneistuspalvelu Oy is a small workshop in Central Finland. Just like thousands of OK-VISE users, they are serving local industry with flexible deliveries and affordable pricing of their services. The young entrepreneur Mikko Mäkelä took over the company from his father in 2015, and since then he has been upgrading the operations and equipment of […]

Lithuanian cases: OK-VISE in 5-axis machnining

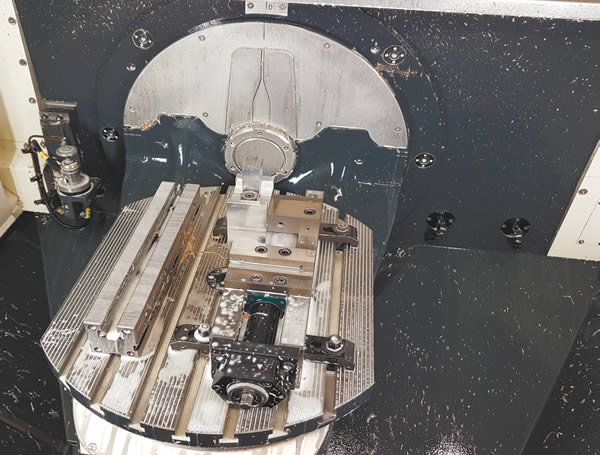

Our first case from Lithuania is a company using vertical 5 axis CNC machines. Machine table is Ø630x500mm. In the most case customer is using standard or dedicated 5-axis machine vises for 5 side machining. When part size is big enough, there is no problem with spindle/tool reachability of part from all 5 sides. What […]

Lithuanian cases: Ignetas UAB

Another example from the company Ignetas UAB, which is a mid-size company, working in the subcontracting field that offers such services as robot welding parts, over moulding parts, semi-automatic and manual riveting parts and complex assembly parts. The company also has some CNC milling machines. They had the task of reducing the production […]

Grid System modules in use

OK-VISE distributor WDS in UK has supplied Grid System components bike parts manufacturer Superstar Components to hold various work piece types, including large aluminium plates. https://www.youtube.com/watch?v=fnWZFObTBUo&list=TLGGAdy8KQcmSaUxMDAzMjAyMw

Swedish subcontractor improving their effectivity

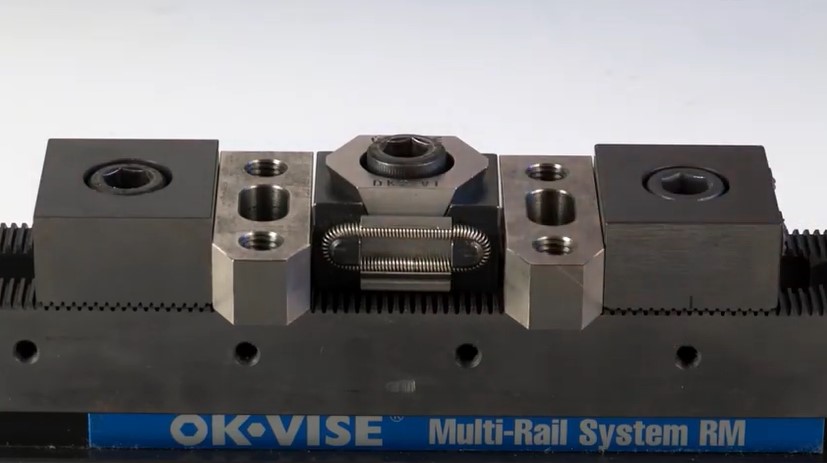

Ljungby CNC is a subcontractor in Sweden, supplying components manufacturers of packing machines and agricultural machinery. They needed a workholding system to clamp several workpieces at a time, with material from hardened steel to aluminum and plastics. After comparing several systems, Ljungby CNC decided for OK-VISE Multi-Rail RM system because it’s flexibility to adapt to […]

Robotic workpiece loading with cobot

Finnish automation specialist Wisematic Oy has developed a simple turn-key solution for machine tending. Techman collaborative robots (cobot) are loading the workpieces to the machining center, and then the OK-VISE Powerplate has been developed and used to automatically hold the workpieces in the machine. Additionally, the co-bot can execute all the actions just like a […]

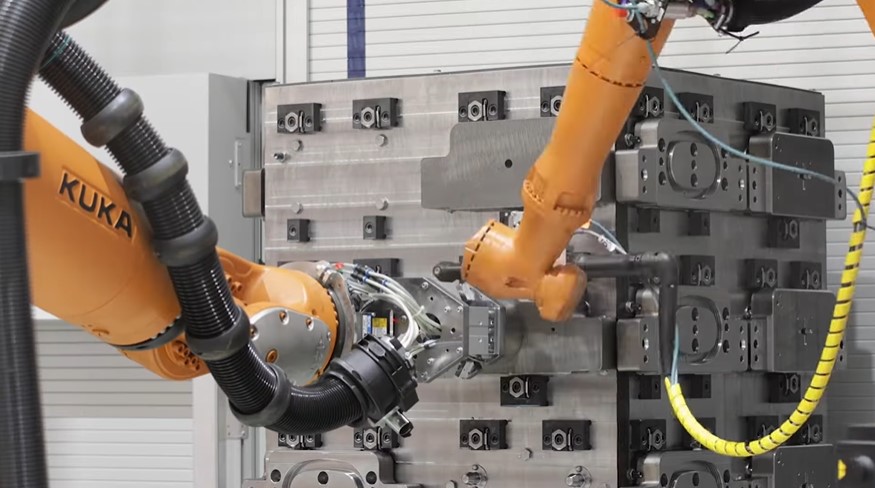

Robotic loading and automated clamping at Rantek Oy, Finland

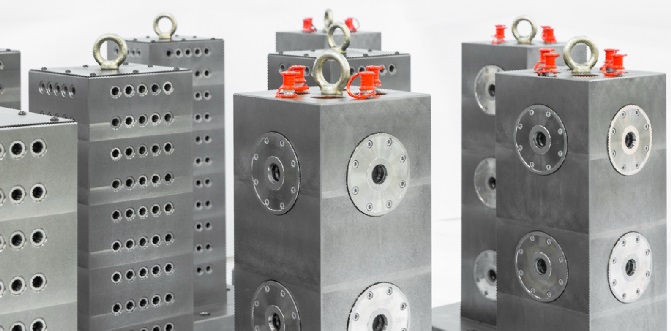

Rantek Oy is an electrical equipment manufacturer who excels in winding, machining and hardware assemblies. They are continuously improving productivity and quality. Their latest investments have been in automation, including robotic loading and FMS. OK-VISE is used regularly in their tooling columns, no matter if workpiece loading is done manually or automatically.