In recent years, especially in low-volume production, there has been an increasing transition from dedicated fixtures to more generic-purpose, modular fixtures. We believe there are several reasons for this shift. One possible and straightforward reason is that as manufacturers continually seek different ways to enhance productivity and reduce production costs, the recognition that well-designed fixturing can significantly support the achievement of these goals has been growing.

Other potential reasons could include the increasing availability of modular fixture systems in the market and the concurrent improvement in their quality. These systems have also become easier to use and understand. Additionally, there is a decline in ‘in-house’ fixture design expertise, making it more challenging to implement new product-specific fixtures in production than before.

In this article, we will explore the various advantages that modular fixture systems can offer in production. We will also explain why you should consider Multi-Rail System when planning to purchase a modular fixturing system.

Advantages of modular fixturing

A modular fixturing system is easy to adjust and reconfigure, making it suitable for a variety of workpieces and production requirements.

Traditional fixturing methods involve creating custom fixtures tailored to each specific part. This process often requires time-consuming design, fabrication, and setup, resulting in limited flexibility and adaptability to changes in production needs. Moreover, if a company lacks an in-house fixture designer, design costs can escalate further. Also, if the design work has been outsourced, the process can be slow.

The modular fixturing system can give you many advantages comparing to traditional fixturing:

1. Flexibility: A modular fixturing system is easy to adjust and reconfigure, making it suitable for a variety of workpieces and production requirements. This flexibility saves time since there’s no need to design and manufacture a new fixture for each job. Existing fixture modules can be used to create new setups swiftly. Additionally, ordering new modular (generic purpose) fixturing components is fast as they are typically stocked items.

2. Cost-effectiveness: Utilizing a modular fixturing system proves to be more cost-effective in the long run compared to traditional fixtures. This is due to their reusability and adaptability. Since modular fixtures consist of standard components, it’s easy to replace broken parts, and a single component can serve multiple purposes.

3. Scalability: As production needs change and expand, modular fixturing system can easily adapt to new requirements by adding or adjusting components. Their adjustability makes them highly scalable for expanding or changing production setups. With components readily available from stock, acquiring necessary parts is both easy and fast, ensuring uninterrupted workflow and operational efficiency.

The traditional downsides associated with modular fixturing, such as precision, clamping forces, and initial costs, have evolved in recent years to nearly match the characteristics of traditional fixturing. Notably, these systems are continuously evolving, indicating ongoing improvements.

Why should you consider Multi-Rail System?

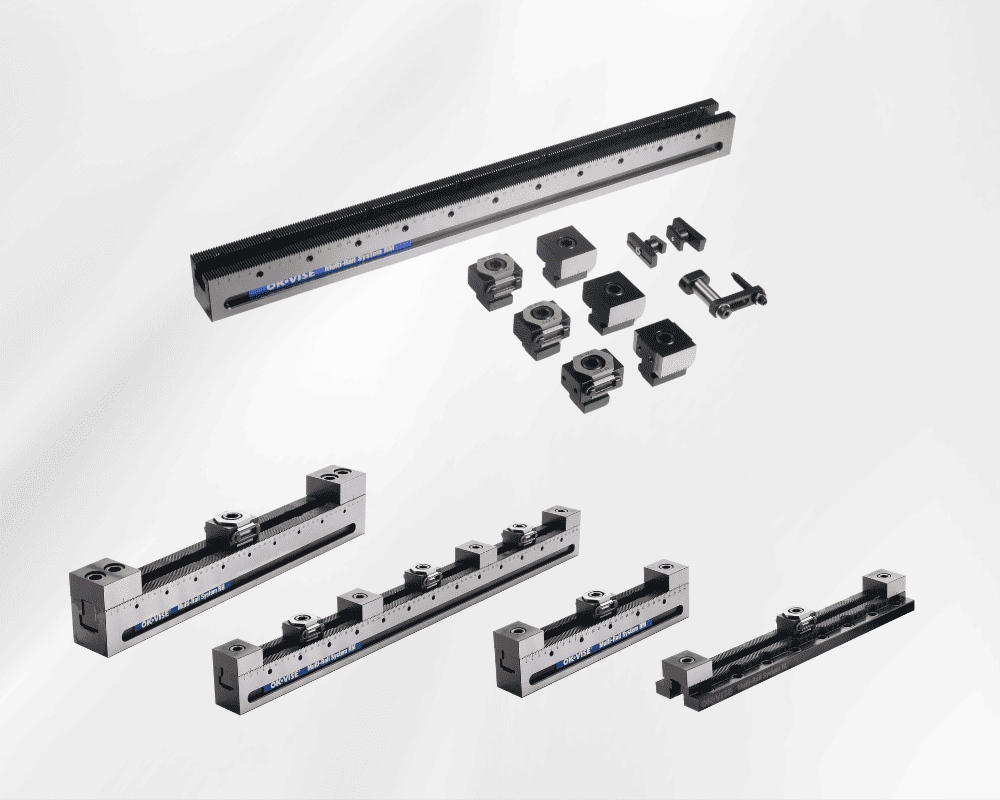

The history of our company goes back to 1984, when OK-VISE started to manufacture the world’s first wedge operated side clamp. However, over the past decade, our focus has shifted towards developing and producing the most accurate and exceptionally reliable rail-based modular fixturing system known as Multi-Rail. While there were existing rail-based systems in the market, the recognition of several improvements of these systems caused us to develop our own system.

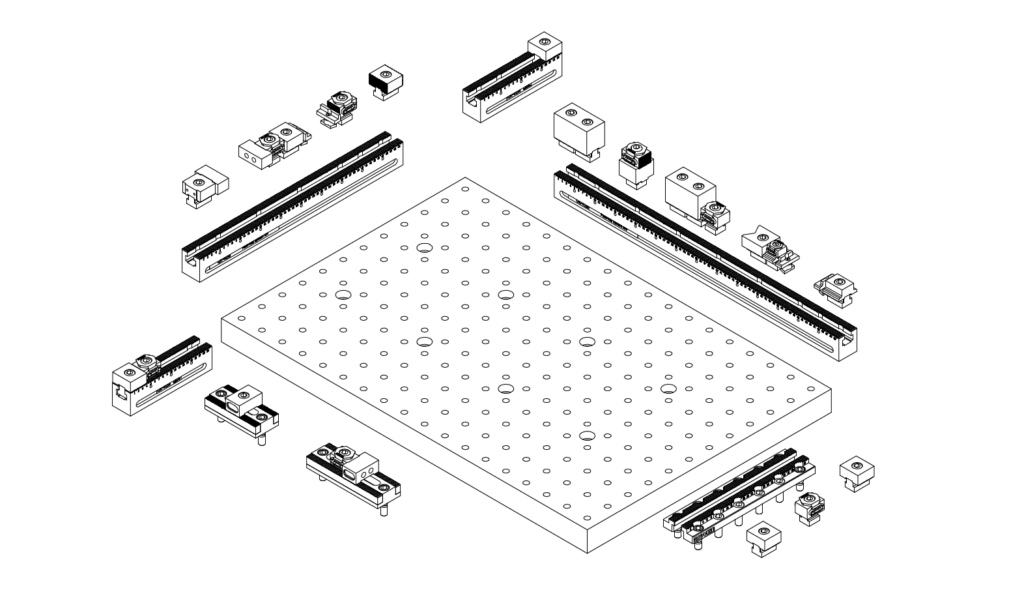

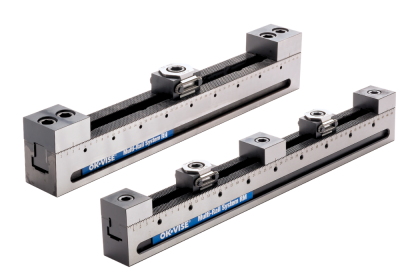

There are some key differences between Multi-Rail and other systems in the market. The Multi-Rail system utilizes a steep serration which makes it extreme stable. The components are also extremely accurate, e. g. in the RM base rail accuracy from every serration to the locator hole is +- 0.01 mm. These factors ensure precise workpiece positioning, program after program, providing unparalleled consistency.

The lengths of the system rails vary between 100 and 850 mm, and the system offers a comprehensive range of components including various stops, clamps, side guides, risers, and floating units. There are also three different base rail options (RL, RM and RH). This wide selection allows customers to tailor their fixturing system to meet their specific needs, and the system is also easily scalable. The use of original OK-VISE low-profile clamps provides high and accurately adjustable clamping forces to the system.

These all are big separating factors between Multi-Rail and other systems on the market. Additionally, our system utilizes OK-VISE low-profile clamps for securing, enabling it to generate huge clamping forces. It can be also easily modified to accommodate different workpieces, thanks to our wide selection of clamp jaws.

More information about the system:

High-quality production leads to high-quality products

The Multi-Rail System is manufactured at OK-VISE’s original facility in Muurame, Central Finland. The production has evolved to meet the high-quality standards expected OK-VISE’s customers, and the development will continue as OK-VISE aims to enhance its ability to serve customers as flexible as possible. We utilize the latest measurement technology to ensure that the properties promised to customers always meet their expectations.

Our sales are conducted through our global distributor network. In addition to our distributors, we also offer technical support whenever needed.

If you want to hear more, please don’t hesitate to contact your nearest distributor or reach out to us for further information.